Pursuit of safety and security

To deliver safe, secure, and high-quality products

At J-OIL MILLS we believe in "Joy for life®-Bringing joy to the future by food," and each and every employee sees things from the customer's perspective and takes food seriously throughout the entire process, from the time our products reach your hands. Our mission at J-OIL MILLS is to provide our customers with safe, secure, and high-quality food.

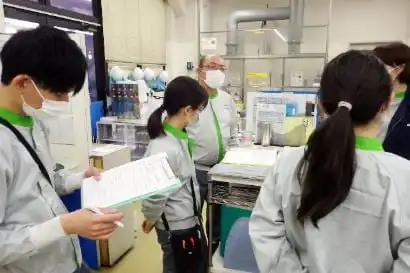

We have established a system where each Department, such as oil and margarine, takes responsibility for creating safe and reliable products. The entire Group is united in our efforts to constantly improve the "safety" and "reliability" of our products.

Furthermore, we strive to improve quality by establishing a management system for all processes, from raw materials to product development, manufacturing, logistics and sales.

quality policy

J-OIL MILLS Group Quality Policy

At the J-OIL MILLS Group, we aim to realize our vision of a future where "Joy for life®-Bringing joy to the future by food" by continually providing safe, secure, and high-quality products and services and by pursuing the happiness of our stakeholders.

【Basic policy】

- We take customer requests seriously, provide appropriate information, and deliver products and services that satisfy customers.

- We will strengthen our partnership with the supply chain and provide safe, secure, and high-quality products and services.

- We strongly recognize that ensuring food safety is the responsibility of food companies, and we comply with related laws and regulations.

- We guarantee quality by continually improving our quality and food safety management systems based on international standards ISO9001 and ISO22000.

- As a quality assurance officer, each and every employee of Group is mindful of food safety and security, and will do our utmost to strengthen our business foundation and improve quality in all stages from planning and development to production, logistics, and sales services.

that's all