Resource circulation

Waste reduction and recycling

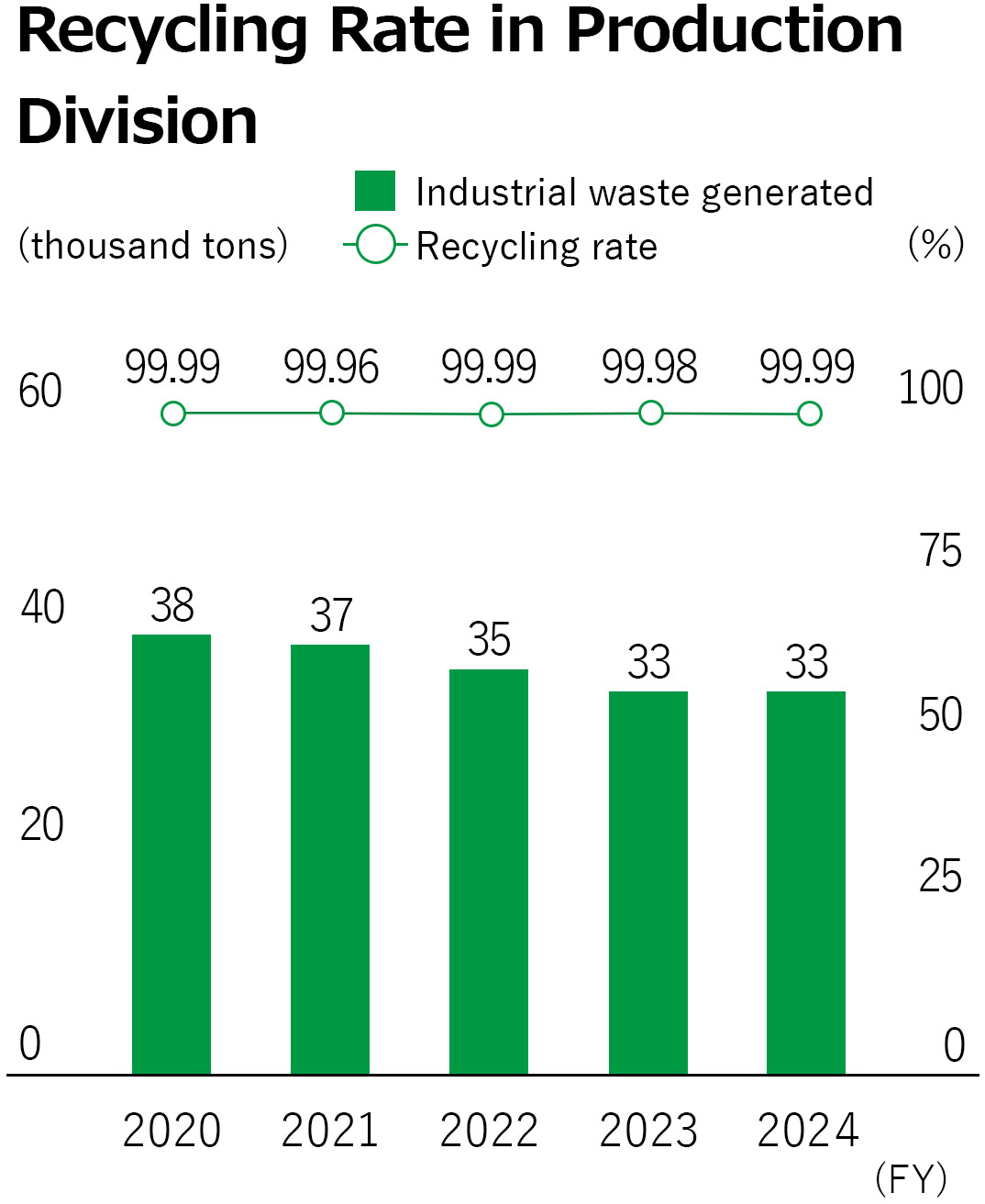

J-OIL MILLS Group promotes waste reduction and recycling, achieving zero emissions* every year. In fiscal 2024, we will continue to promote the conversion of waste into valuable resources, maintaining our target recycling rate of over 99.9% in our production divisions. We will continue to strive to reduce the amount of initiatives, raw materials, water, and other inputs, and will work to reduce and recycle pollutants and waste emissions. Furthermore, we are working to reduce the use of fossil fuel-derived plastics, and non-production divisions are also implementing e-learning and environmental seminars on waste, working to maximize resource utilization efficiency across the company.

*At our company, we define zero emissions as not simply incinerating or disposing of industrial waste generated from Plant and offices in landfills (recycling rate of 99.9% or more).

Conservation of water resources

Water is an important resource that is indispensable throughout the supply chain, from the cultivation of raw crops to the manufacturing process of products. In particular, our factories use water in various forms, such as for steam and as a cooling medium, and we recognize that conserving water resources is a critical issues.

Under the leadership of Sustainability Committee, chaired by Member of the Board, we strive to reduce water usage and accurately understand water risks, and are working to reduce our environmental impact through planned measures.

Reducing water usage

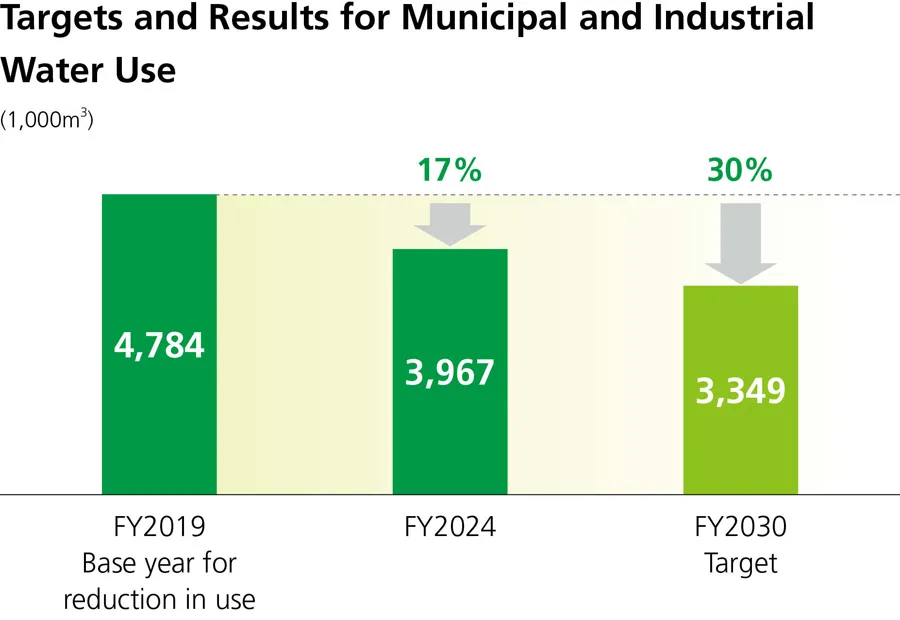

The Group has set a target of reducing city and industrial water usage by 30% by fiscal 2030 compared to fiscal 2019, and is working to reduce water withdrawals by promoting efficient water use and reuse. Water usage at all domestic Plant in fiscal 2024 will be 3,967,000 m3, a 17% reduction compared to fiscal 2019.

To ensure effective use of water resources, we are working to further reduce water use and achieve sustainable water usage by strengthening water usage monitoring, promoting water resource recycling, and making integrated improvements to operations and facilities to increase water efficiency.

Water risk assessment

The Group is identifying and managing significant risks related to water resources at its domestic production bases. Using analysis results from Aqueduct*1 and other sources, we conducted an assessment of water risks and opportunities at six domestic manufacturing Plant, focusing on factors such as the local water environment, the impact on business, and the likelihood of occurrence. As a result, we found no water intake from areas with high baseline water stress*2, but identified a risk of flood damage from typhoons and high tides at four sites. These sites are taking specific measures, such as installing flood barriers and updating high tide prevention equipment.

Going forward, we will continue to strive to reduce water risks, which are important to us as a food company, and will further strengthen initiatives to protect water resources with the aim of protecting the environment and ensuring business continuity.

*1 Aqueduct: A global water risk assessment tool provided by the World Resources Institute (WRI)

*2 Baseline water stress: The ratio of water demand to available and renewable surface and groundwater supplies. The higher the value, the more intense the competition between users.

Proper management of chemical substances

Regarding the chemical substances we handle, we strive to properly manage them in accordance with laws and regulations such as the Act on Promotion of the Reporting and Management of Chemical Substances (PRTR Act), and we also manage other chemical substances appropriately.

Regarding PCB waste, we are reporting the storage of PCB waste and conducting systematic treatment based on the Act on Special Measures Concerning Promotion of Proper Treatment of Polychlorinated Biphenyl Waste (PCB Special Measures Act).

Guidelines for containers and packaging

| Guidelines for containers and packaging |

|---|

| We will explore new technologies for recycling containers and packaging such as bottles, cans, and paper, and strive to adopt them. |

| We strive to develop environmentally friendly products, such as product designs that reduce the amount of plastic containers and packaging used, as well as plant-based materials and easily recyclable materials. |

| We will promote the adoption of FSC-certified paper. |

| We will promote material procurement from ESG-friendly companies. |

| We strive to develop containers and packaging that can accommodate a variety of users. |

| We consider the entire supply chain and address transportation efficiency and labor shortages. |

Initiatives plastic issues

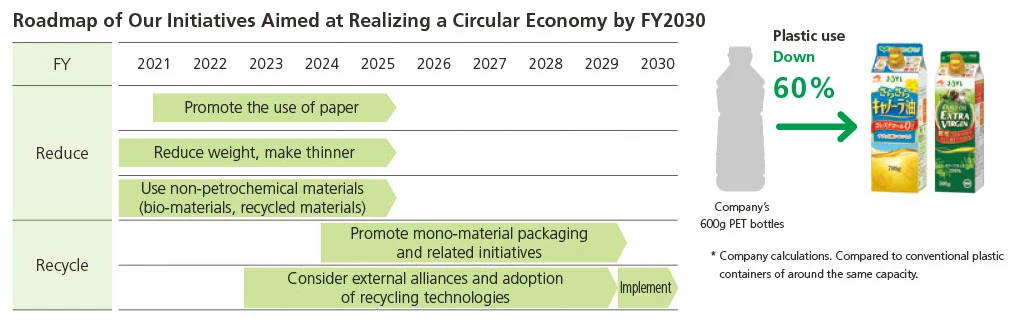

In May 2022, we established a goal of achieving "zero plastic waste" by fiscal 2030.

In 2021, we set a goal of reducing plastic waste by 25% by 2030 compared to fiscal 2000, and have been implementing various initiatives to achieve this goal. However, following the enforcement of the Act on Promotion of Resource Recycling Related to Plastics, we believe that we need to initiatives even harder than ever to reduce plastic waste, which causes marine environmental pollution and climate change, and have therefore revised our target upward.

To achieve this goal, we will work to develop and sell environmentally friendly products by expanding our "Smart Green Pack" series of environmentally friendly products that use paper cartons, adopting biomass resins, reusing waste plastic and utilizing recycled resins, and promoting the development of recycling technologies through corporate collaboration. The "Smart Green Pack" series initiatives environmental friendliness, reducing plastic usage by more than 60%* and CO2 emissions by more than 26%*, with ease of use thanks to a double cap that allows for the adjustment of pouring volume. We will continue to work to reduce our environmental impact by changing specifications to recyclable packaging and establishing new recycling technologies through corporate collaboration.

Initiatives to reduce the weight of plastics

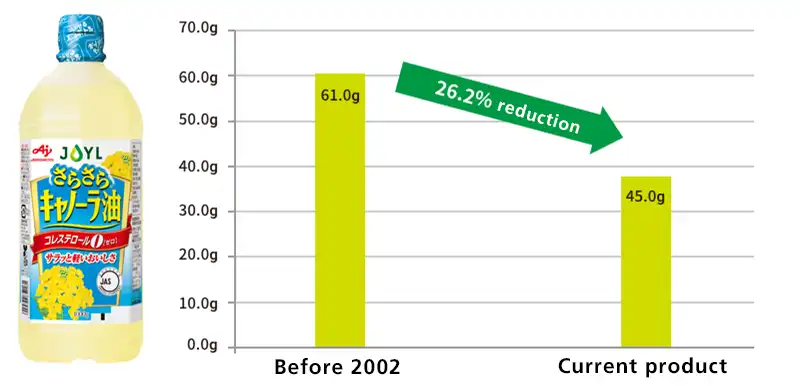

We have been actively working to reduce and lighten the amount of plastic used in our main packaging and containers for some time now. In collaboration with container and material manufacturers, we have promoted weight reduction initiatives, and the weight of Eco Bottles (polyethylene bottles), which are used as containers for our main household oils and fats products, has been reduced by 26.2% compared to before 2002. In addition, the weight of UD Eco Pet (PET bottles), another main product container, has been reduced by 20.0% compared to before 2007.

1000g eco bottle bottle weight trend

600gUD*Ecopet Pet weight trends

*Universal design

Initiatives to reduce plastic

"Smart Green Pack" is an environmentally friendly product that uses paper packs

The "Smart Green Pack" series is a series that pursues packaging functionality and environmental friendliness by using paper cartons, which are rare for oils and fats products, as containers in order to promote the reduction of plastic waste and CO2, which are our priority initiatives. After launching two products in August 2021, the series will be launched in spring 2022.

"Smart Green Pack" series

Recycled PET resin is used for the bottle and part of the label

In February 2024, we released a new product and renewed it, and we are now using recycled PET resin made from refurbished and recycled used PET bottles for some of the bottles and labels. We will continue to expand similar initiatives in the future.

Product design aimed at realizing “low load” value

We define low-impact products as those that address one of three factors: (1) the global environment, (2) the work environment, or (3) the depletion of food resources, and we aim to achieve a 100% low-impact product ratio by fiscal 2030. Furthermore, with the aim of contributing to reducing the burden on society and the environment, we have formulated the "Environmental Guidelines for Realizing 'Low-Impact' Value." Based on these guidelines, we will proactively incorporate our corporate philosophy of reducing environmental impact from the product design and development stage. From fiscal 2023, we will introduce an environmental checklist into product design, and strive to improve the consistency and appropriateness of our internal and external communications in order to realize our "Joy for Life-Bringing joy to the future by food" philosophy.