Quality Inspection and Shipping

Quality inspection

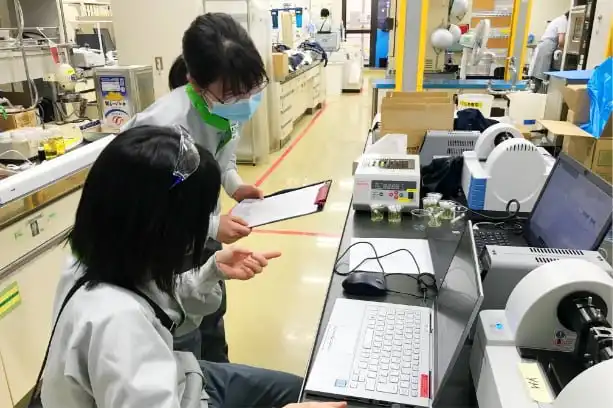

The quality control room at each Plant conducts various inspections to ensure safety and peace of mind for our customers. From the time we receive raw materials to the products we deliver to our customers, we deliver products of even more reliable quality by subjecting them to rigorous inspections, including analysis using equipment and sensory tests such as taste.

Shipping

Product shipping: After strict inspection, the product is finally shipped.

Products packed in cardboard boxes are stacked onto pallets by a "palletizer", an automatic stacking robot. Products loaded on pallets are loaded onto cargo trucks using forklifts and shipped. If the product has a long time to ship, it will be stored in a warehouse and strictly controlled until it is shipped.